CHANGING BEHAVIOR TO PRODUCE RESULTS®

LCE built the Life Cycle Institute to share maintenance and reliability subject matter expertise with the world. Through certifications, coaching, and a focus on real-world application, Institute programs turn training into lasting results.

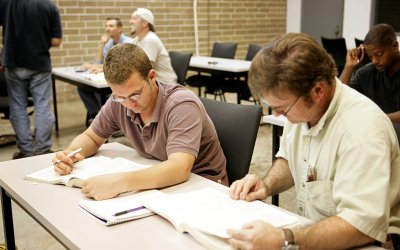

Instructor-Led Training

Whether you learn better in a classroom or from your own work station, we have the solution for you

eLearning Courses

Our online training transforms best practices into challenging, engaging, and performance-driving eLearning

Private/Group Training

Considering training team members? We offer group discounts and can bring our experts to your location, saving time and travel

Certifications

Looking to grow your skillset or gain credibility with a credential? Our university-backed programs deliver results in a format that works best for you

Life Cycle Institute Alumni

What makes us different? High Impact Learning.

Learning is change. Change is learning®. Today’s competitive advantage goes to those who can learn, adapt, and innovate faster. For this reason, LCE started the Life Cycle Institute -- a division dedicated to human performance improvement -- as a way to share asset management and reliability subject matter expertise with the world. Our approach to training is different. We call it High Impact Learning. High Impact Learning is executed through our 3A Learning® process that integrates learning, leadership, and change management techniques to produce documented, sustainable results. When you partner with the Life Cycle Institute for your performance improvement needs, you will experience learning that changes behavior and produces results. For more on the Institute's 3A Learning® process, click the logo below.

Partnerships and Affiliations